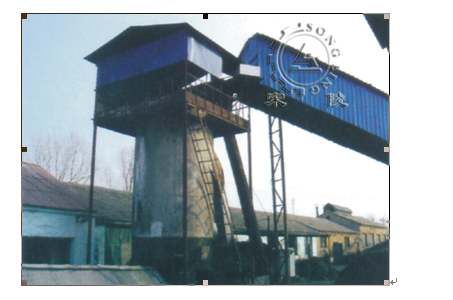

Tower Dryer

Introduction of Tower Dryer:

Tower drying equipment, also called tower dryer, is designed for the dehydration of briquette and pellet. It has reasonable design, high thermal efficiency, good drying effect and adjustable air volume.

This type of tower dryer is made of steel structure; inner lining adopts heat preservation materials to keep warm; multilayer high temperature castings are adopted in the roaster; there are vibration system, interception system, temperature control system and intelligent control system installed on some relevant parts of the machine; vapor and smoke are collected with the application of a draught fan and a cyclone dust collector.

Working principle of Tower Dryer:

It adopts vertical equipment and steel shell, lined with insulation material to prevent losing the heat and multi-layer high-temperature kiln casting which are overlapping with each other. All relevant parts including the uppe, middle and lower parts are designed with several group of vibrating, closure, temperature-control and intelligent system. And therefore, water vapor and smoke can be absorbed by the dust collector. Materials enter from the top of the elevator, slip evenly down to the bottom through the powder mill and vibrating feeder of its own internal dynamic diameter, and exchange with the rising hot air currents reversely, and thus are dried layer by layer. Eventually, qualified materials are unloaded by electric vibrating motor and transported to the designated place by belt conveyor where they are needed.

Main Technical Parameters of Tower dryer:

|

model

|

Original moisture

|

Eventually moisture

|

Standard coal consumption

(kg/t)

|

Capacity (t/h)

|

Electricity consumption (kw/t)

|

weight (t)

|

|

LH-2012

|

25%

|

2%

|

6~7.8

|

8~10

|

2~3

|

17

|

|

LH-2014

|

25%

|

2%

|

7~8.6

|

9~12

|

1.8~2.6

|

19

|

|

LH-2016

|

25%

|

2%

|

8~11

|

10~14

|

1.6~2.2

|

21

|

|

LH-2216

|

25%

|

2%

|

9~12

|

12~15

|

1.5~2.1

|

26

|

|

LH-2218

|

25%

|

2%

|

10~13

|

14~16

|

1.5~2.0

|

28

|

|

LH-2220

|

25%

|

2%

|

11~13.8

|

15~17

|

1.4~1.8

|

30

|

|

LH-2222

|

25%

|

2%

|

13~15

|

16~19

|

1.4~1.6

|

32

|

|

LH-2516

|

25%

|

2%

|

17~22

|

18~26

|

1.4~1.6

|

38

|

|

LH-3018

|

25%

|

2%

|

22~27

|

23~32

|

1.4~1.8

|

45

|

Note: The technical parameters above are just for your reference. If there is any change, all parameters and overall dimension are subject to operating instructions. Any questions please feel free to contact us.

- Introduction of gold trommel machine

- Mill balls and water influence the effic

- Fault handling of jaw crusher

- process of Stone Aggregates produced by

- How to maintain ball mill with the lubri

- China mining machinery need technology i

- How to choose jaw crusher--let me help y

- Domestic Mining Machinery Trends brief a

- The future development trends and prospe

- The development of ball miller feeding

- Songling advise for the purchase skills

- Mining mechanization hot ascension of Mi

- The property of Flotation Machine

- The Most Important Factor in the Process

- Obvious advantages of ball mill

- Environmental Protection Idea must be st

- The Benefits of central bank cutting int

- Stone production industry promote the c

- The future of the drying equipment in Ch

- Rock Crusher Maintenance

Jenny

Jenny