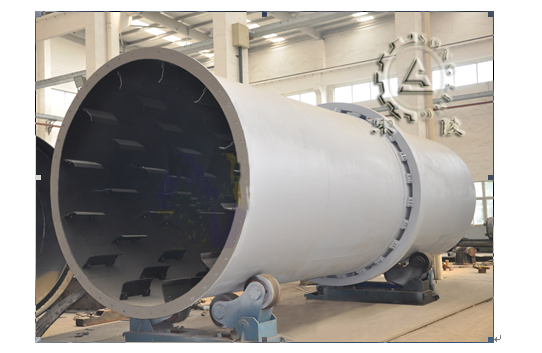

Rotary drum drier

Applications of Rotary Drum Dryer

Applicable for drying big particles, heavy particles in chemical, mining, and metallurgy, such as mining area, cinder of blast furnace, coal, powder of metal, phosphate fertilizer and thiamine.

For drying the powder or particles with special requirements, such as HP foaming blowing agent, residule of alcohol, light calcium carbonate, active clay, magnetic powder, graphite, and residue of medicine. For materials to be dried under low temperature and large lot continuous production

Applicable for drying big particles, heavy particles in chemical, mining, and metallurgy, such as mining area, cinder of blast furnace, coal, powder of metal, phosphate fertilizer and thiamine.

For drying the powder or particles with special requirements, such as HP foaming blowing agent, residule of alcohol, light calcium carbonate, active clay, magnetic powder, graphite, and residue of medicine. For materials to be dried under low temperature and large lot continuous production

Features of Rotary Drum Dryer

The motorization level of the barrel is high, and the production capacity is high.

The resistance that the material passes through the barrel is less, and the power consumption is low.

Application capability to different characters of materials is high.

The operation is stable, the operation fee is low, and the uniformity of product drying is good.

The motorization level of the barrel is high, and the production capacity is high.

The resistance that the material passes through the barrel is less, and the power consumption is low.

Application capability to different characters of materials is high.

The operation is stable, the operation fee is low, and the uniformity of product drying is good.

Technical Parameters of Rotary Drum Dryer

|

item (m)

|

productive capacity (t/h)

|

revolution (r/min)

|

motor power (kw)

|

install angle (degree)

|

Temp. of final

|

|

ø1.0×5.0

|

0.5-1.2

|

0.6-6

|

4

|

3-5

|

≤1.5%

|

|

ø1.2×6-10

|

1.5-3

|

0.6-6

|

5.5

|

3-5

|

≤1.5%

|

|

ø1.5×12-18

|

3-5.5

|

0.6-6

|

15

|

3-5

|

≤1.5%

|

|

ø1.8×12-18

|

5-6.5

|

0.6-6

|

18.5

|

3-5

|

≤1.5%

|

|

ø2.2×12-22

|

7-12

|

0.6-6

|

22

|

3-5

|

≤1.5%

|

|

ø2.4×15-20

|

9-15

|

0.6-6

|

30

|

3-5

|

≤1.5%

|

|

ø3.0×25

|

16

|

0.6-6

|

55

|

3-5

|

≤1.5%

|

Note: The technical parameters above are just for your reference. If there is any change, all parameters and overall dimension are subject to operating instructions. Any questions please feel free to contact us.

- Introduction of gold trommel machine

- Mill balls and water influence the effic

- Fault handling of jaw crusher

- process of Stone Aggregates produced by

- How to maintain ball mill with the lubri

- China mining machinery need technology i

- How to choose jaw crusher--let me help y

- Domestic Mining Machinery Trends brief a

- The future development trends and prospe

- The development of ball miller feeding

- Songling advise for the purchase skills

- Mining mechanization hot ascension of Mi

- The property of Flotation Machine

- The Most Important Factor in the Process

- Obvious advantages of ball mill

- Environmental Protection Idea must be st

- The Benefits of central bank cutting int

- Stone production industry promote the c

- The future of the drying equipment in Ch

- Rock Crusher Maintenance

Jenny

Jenny